Leaving a corporate sector job with thirteen years of experience in iron and steel sector, Sumanta Kumar Sahoo of Kalinga Vihar, Bhubaneswar took a decision to become an entrepreneur producing hollow-cement block construction bricks. The decision was not easy. His participation in a course on youth entrepreneurship development in IED Bhubaneswar, strengthened his resolve to take the risk. The doubts that he had in his mind vanished after he attended the course. The promise that he got from the Institute to hold his hand at the time of need during the project cycle made him think that he has been already empowered. And thereafter, he whole heartedly plunged into the venture.

With just Rs. 1.25 lakh seed capital, he started the unit investing Rs. 20 lakh in fixed capital and Rs. 5 lakh as working capital. With a very high loan component (Rs. 23.75 Lakh), he adopted a strategy to have the best available proven technology and skilled personnel. He himself supervised input supply and operations. He is now a successful entrepreneur, earning between 80,000 to 90,000 rupees per month. Because he himself supervises the operations and ensures supply of good quality products, the demand from construction industry for his products is quite high. He intends to expand his operation soon.

From a diploma holder in electrical engineering and a technician in a corporate house, with much lower than his expectation about his salary, he has become a full-fledged entrepreneur, a risk taker. He is currently providing employment to 10 persons, all female. He has been repaying his loan instalments regularly and banks in his area are eager to provide him adequate finance for expanding his business.

From a diploma holder in electrical engineering and a technician in a corporate house, with much lower than his expectation about his salary, he has become a full-fledged entrepreneur, a risk taker. He is currently providing employment to 10 persons, all female. He has been repaying his loan instalments regularly and banks in his area are eager to provide him adequate finance for expanding his business.

He says, thanks to guidance received during his training in IED and follow up advice, as and when he needs. The young people in his area are looking forward to him. He thanks his trainers in the Institute and the government functionaries for helping him in his earnest endeavour.

For Sabita Subhadarshan, of Jharpada, Bhubaneswar, being recognized by the government as an entrepreneur, is a dream come true. This transformation was the result of her own strong will, her capacity building coming through a training programme in the Institute of Enterpreneurship Development (IED), Bhubaneswar, and the facilitation done by the Institute for finance needed for the business.

She chose to produce incense sticks which have good local demand. With a small financial investment of just Rs. 3 lakh, she produces incense sticks in her own enterprise Divya Industries. She markets quality products and earns Rs. 7,000/- per month as a net income. This business she does at her free time in between her engagement as a home-maker. It may seem unbelievable. But she has given employment to six persons, three male and three female, who earn to improve financial status of their families.

She chose to produce incense sticks which have good local demand. With a small financial investment of just Rs. 3 lakh, she produces incense sticks in her own enterprise Divya Industries. She markets quality products and earns Rs. 7,000/- per month as a net income. This business she does at her free time in between her engagement as a home-maker. It may seem unbelievable. But she has given employment to six persons, three male and three female, who earn to improve financial status of their families.

She is confident and now planning to expand her business to go beyond the local market. Is definitely a source of inspiration for many who have a dream to be an entrepreneur.

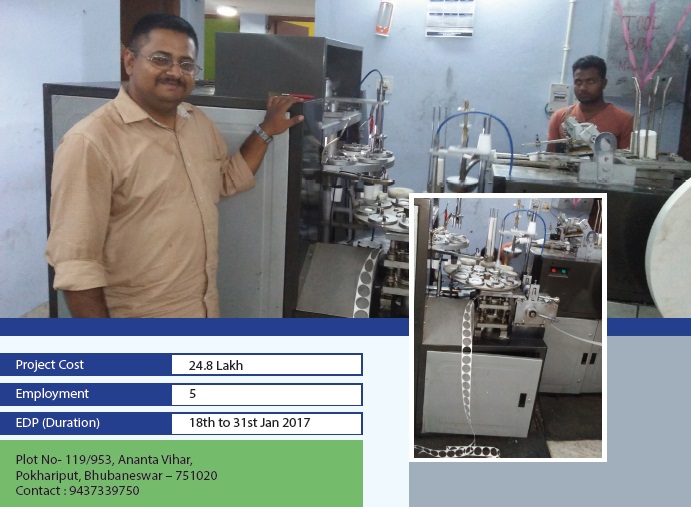

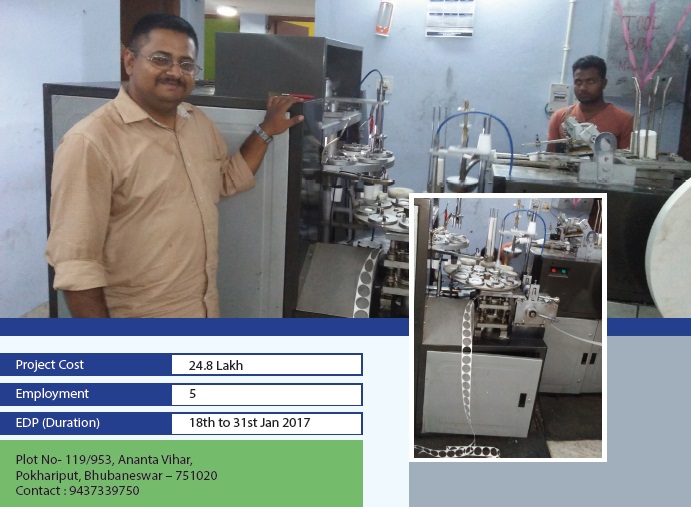

A qualified person- Chandan Chatterjee completed ITI from Kupajal Institute, Diploma in Mechanical Engineering from CV Raman College and Training from CTTC, Bhubaneswar. From his student life he had a passion towards understanding and working with technologies. He used to repair different machineries and do maintenance of machine parts. Although his parents are service holders, he had a dream from childhood to establish an enterprise of his own.

The turning point came while he joined the EDP training under Institute of Entrepreneurship Development, Bhubaneswar. During training, he got an opportunity to visit MSME trade-fare at Exhibition Ground, Bhubaneswar. There he saw a machine for automatic paper cup. He made enquiries about the working of the machine, performance & the price etc. and impressed on the exhibitors not to take away the same from Bhubaneswar. He kept the machine in his place and after the training, he setup his own unit to produce the Eco-friendly paper cups.

Chandan has employed four persons apart from fruitfully engaging him in his business. He is happy with his current level of production and sales, which takes care of his own needs and repayment obligations. However, he has the high ambition of becoming an established industrialist, which will help him contribute to economic growth and employment generation, apart from his own enrichment.

Chandan has employed four persons apart from fruitfully engaging him in his business. He is happy with his current level of production and sales, which takes care of his own needs and repayment obligations. However, he has the high ambition of becoming an established industrialist, which will help him contribute to economic growth and employment generation, apart from his own enrichment.

The real heroes live amongst us. But they often go unnoticed till their efforts get recognized. They don’t make a fuss about difficulties, rather they find solutions to the problems, they face from time to time. They don’t look for excuses behind a failure, rather they work extra hard to make sure they overcome the challenges.

Prasant Kausik (24 years), a young entrepreneur is one of such heroes. He has come all the way from Delhi with his father Mr. Jogendra Kausik, mother Mrs Bimla Kausik and two sisters to set up his dream business at Pipili, in Puri district. After completion of B-Tech in Electrical Engineering, he got an opportunity to join in a good company with a high salary package in campus placement. But after few days of joining, he left the job because he was not satisfied with it.

Since, Prasant’s dreams were different and were always pushing him to start his own enterprise, his father Jogendra Kusik also inspired his son to start his own business. While planning for some business, he got opportunity to undergo an Entrepreneurship Development training at Institute of Entrepreneurship Development (IED), Bhubaneswar. There he met Sri B.B. Mishra sir of IED Odisha who guided him to set up his coir unit on availing loan assistance under Coir Udyami Yojana (CUY). He used his father’s past work experience as a Mechanical Engineer and took his advices regarding investment, return on investment etc.

Finally, after market survey, research and analysis on coir, he he decided to set up his own defibering enterprise at Siriapur, Pipli with investment of Rs 45 lakh. He could avail Rs 10.00 Lakh as loan under Coir Udyami Yojana (CUY) of Coir Board. Prasant’s unit is doing well, producing coir fiber from coconut husk. His unit is the main source of raw material for other micro enterprises producing yarn, coir rope, broom, coir dust etc., both locally and outside, providing employment to 17 people (male and female)

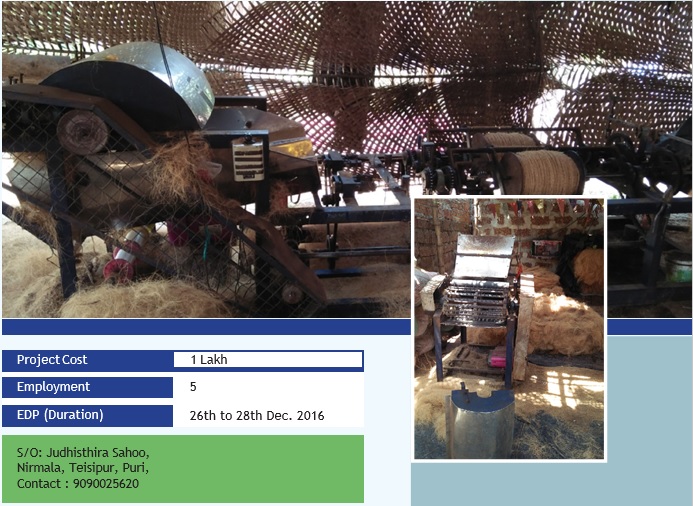

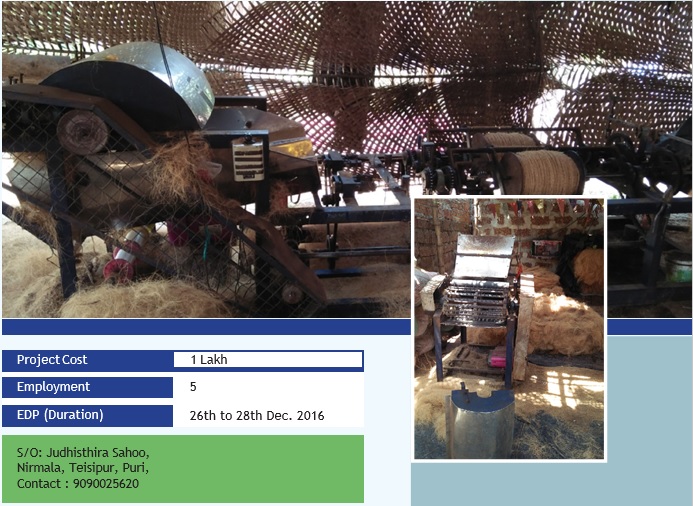

He was comfortable helping in family business of selling sweetmeat, without much effort. But he had a desire to have an enterprise of his own. The EDP course gave this young man Bishnu Prasad Sahoo, the opportunity to be the owner entrepreneur in a coir unit, in his native place, Teisipur, Puri.

After his training, during which, he learnt about the coir industry, the technology, production process and marketing, where to get credit and how to manage them all to earn profit, he started a small unit borrowing Rs. 1 lakh from a bank. He purchased and installed the machinery, got electricity connection, hired five workers, three female and two male, and started production.

He does not have to go anywhere for selling his products, door mats and coir ropes. Customer business men come to his factory and pick up the product by paying cash. Although just a year old, his annual turnover is around Rs 10 lakh and a net profit of Rs 1.80 lakh, which in the local area, is considered as decent income for a beginner. He is in the process of additionally investing Rs. 2 lakh which would more than treble his production and sales.

He is fulfilling the twin objective of providing employment with gender equity while spreading the positive results of government policy of inclusive development.

From a diploma holder in electrical engineering and a technician in a corporate house, with much lower than his expectation about his salary, he has become a full-fledged entrepreneur, a risk taker. He is currently providing employment to 10 persons, all female. He has been repaying his loan instalments regularly and banks in his area are eager to provide him adequate finance for expanding his business.

From a diploma holder in electrical engineering and a technician in a corporate house, with much lower than his expectation about his salary, he has become a full-fledged entrepreneur, a risk taker. He is currently providing employment to 10 persons, all female. He has been repaying his loan instalments regularly and banks in his area are eager to provide him adequate finance for expanding his business.

She chose to produce incense sticks which have good local demand. With a small financial investment of just Rs. 3 lakh, she produces incense sticks in her own enterprise Divya Industries. She markets quality products and earns Rs. 7,000/- per month as a net income. This business she does at her free time in between her engagement as a home-maker. It may seem unbelievable. But she has given employment to six persons, three male and three female, who earn to improve financial status of their families.

She chose to produce incense sticks which have good local demand. With a small financial investment of just Rs. 3 lakh, she produces incense sticks in her own enterprise Divya Industries. She markets quality products and earns Rs. 7,000/- per month as a net income. This business she does at her free time in between her engagement as a home-maker. It may seem unbelievable. But she has given employment to six persons, three male and three female, who earn to improve financial status of their families.

Chandan has employed four persons apart from fruitfully engaging him in his business. He is happy with his current level of production and sales, which takes care of his own needs and repayment obligations. However, he has the high ambition of becoming an established industrialist, which will help him contribute to economic growth and employment generation, apart from his own enrichment.

Chandan has employed four persons apart from fruitfully engaging him in his business. He is happy with his current level of production and sales, which takes care of his own needs and repayment obligations. However, he has the high ambition of becoming an established industrialist, which will help him contribute to economic growth and employment generation, apart from his own enrichment.